Lernen Sie Ihren globalen Partner

für innovative und nachhaltige

Reel-to-Reel-Lösungen kennen

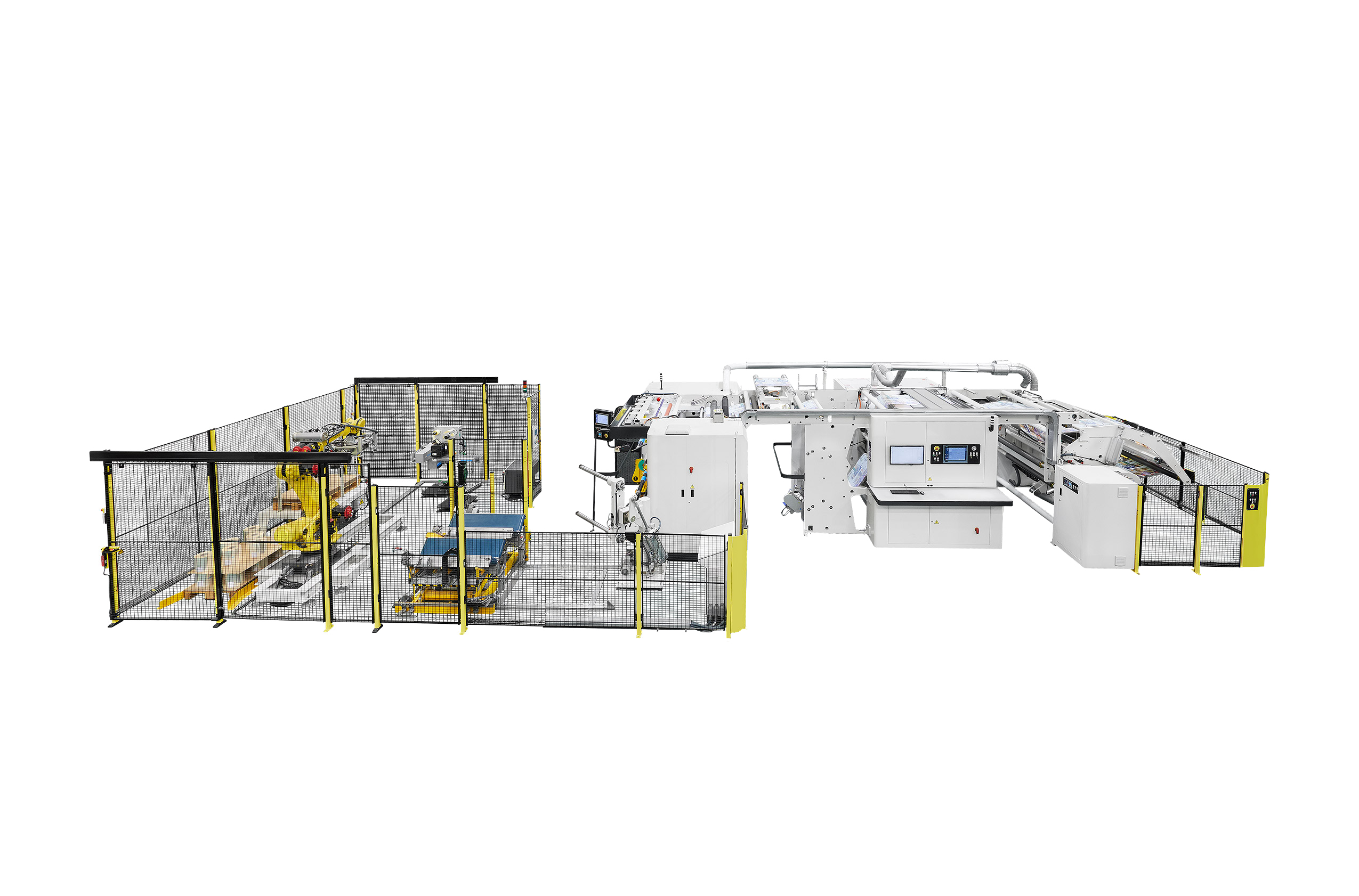

Wir bieten globale Lösungen in den Bereichen Drucken, Kaschieren und Längsschneiden

Wir sind ein globaler Partner für den Bereich flexible Verpackungen. Vom Druck bis zur End-of-Line-Automatisierung bietet Comexi eine breite Palette an innovativen Lösungen. Unser Rundum-Service steht Ihnen von Beginn an und während des gesamten Lebenszyklus Ihrer Maschine zur Verfügung.

Bleiben Sie auf dem Laufenden mit den neuesten Nachrichten und entdecken Sie die wichtigsten Ereignisse in unserer Rubrik „Aktuelles“!

Comexi leitet innovatives MADAM-Projekt zur Verbesserung der Verpackungsproduktion

Comexi leitet innovatives MADAM-Projekt zur Verbesserung der Verpackungsproduktion Comex ist stolz darauf,...

Pionierarbeit in Sachen Innovation und Nachhaltigkeit: Einblicke von Manel Xifra, dem Präsidenten von Comexi, und Abdul Jebbar, dem Gründer von Hotpack Global

Pionierarbeit in Sachen Innovation und Nachhaltigkeit: Einblicke von Manel Xifra, dem Präsidenten...

Comexi Opens Asia-Pacific Hub in Bangkok

Comexi Opens Asia-Pacific Hub in Bangkok July 24, 2023 The opening of...