Rencontrez votre partenaire mondial

pour des solutions novatrices et durables

bobine-bobine

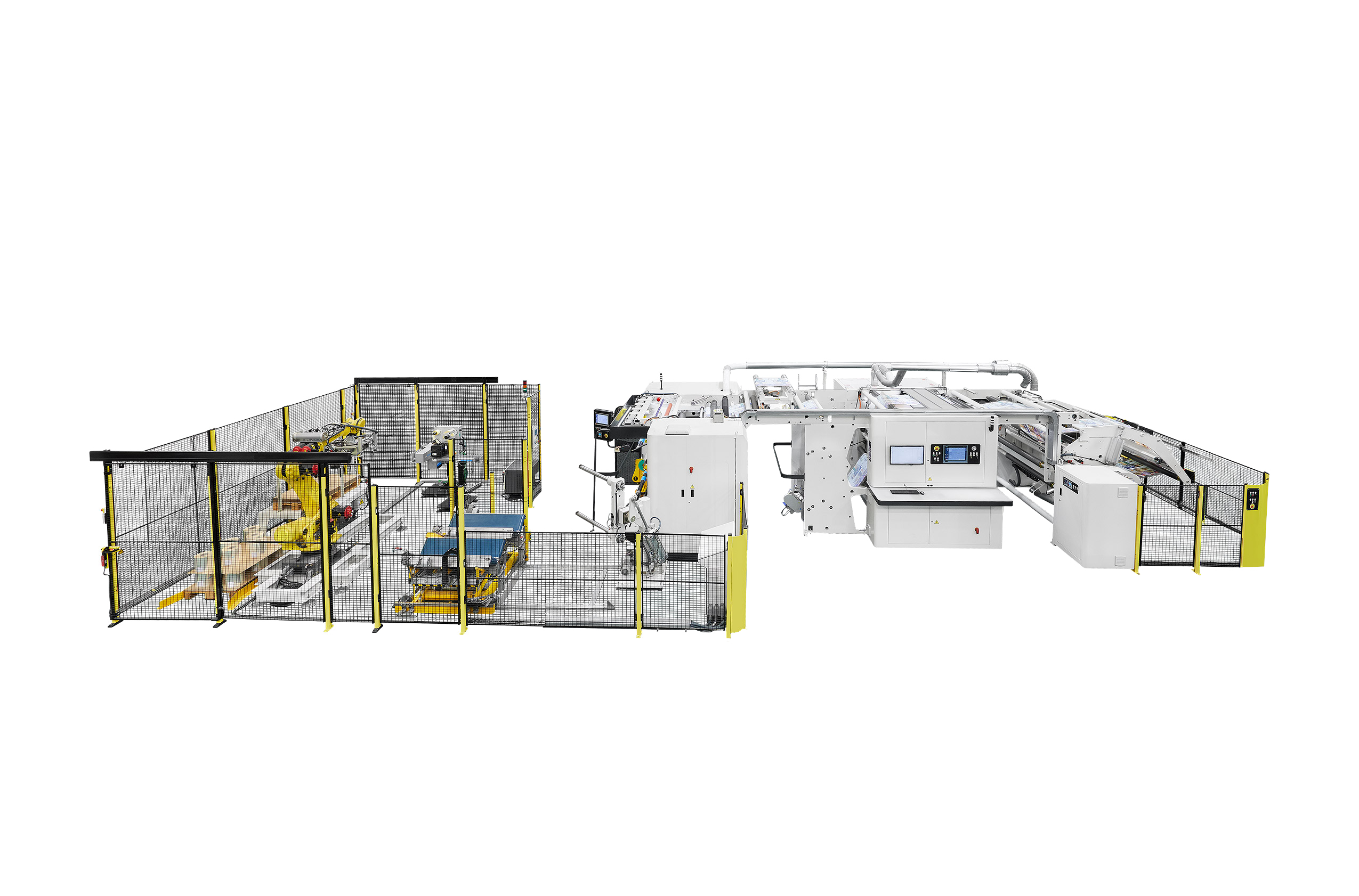

Nous offrons des solutions globales dans l'impression, le laminage et la découpe

Nous sommes un partenaire mondial pour l'emballage flexible. Avec des processus allant de l'impression à l'automatisation de fin de ligne, Comexi vous offre un large éventail de solutions novatrices. Notre service 360° est à vos côtés dès le début et tout au long du cycle de vie de la machine.

Maintenez-vous à jour grâce aux dernières nouvelles et découvrez les évènements les plus importants dans notre section Dernières Nouvelles !

Comexi dirige le projet révolutionnaire MADAM pour l’amélioration de la production d’emballages

Comexi dirige le projet révolutionnaire MADAM pour l'amélioration de la production d'emballages...

Pionnier de l’innovation et de la durabilité : Points de vue de Manel Xifra, président de Comexi, et d’Abdul Jebbar, fondateur de Hotpack Global

Pionnier de l'innovation et de la durabilité : Points de vue de...

Comexi Opens Asia-Pacific Hub in Bangkok

Comexi Opens Asia-Pacific Hub in Bangkok July 24, 2023 The opening of...