Meet your global partner

for innovative and sustainable

reel to reel solutions

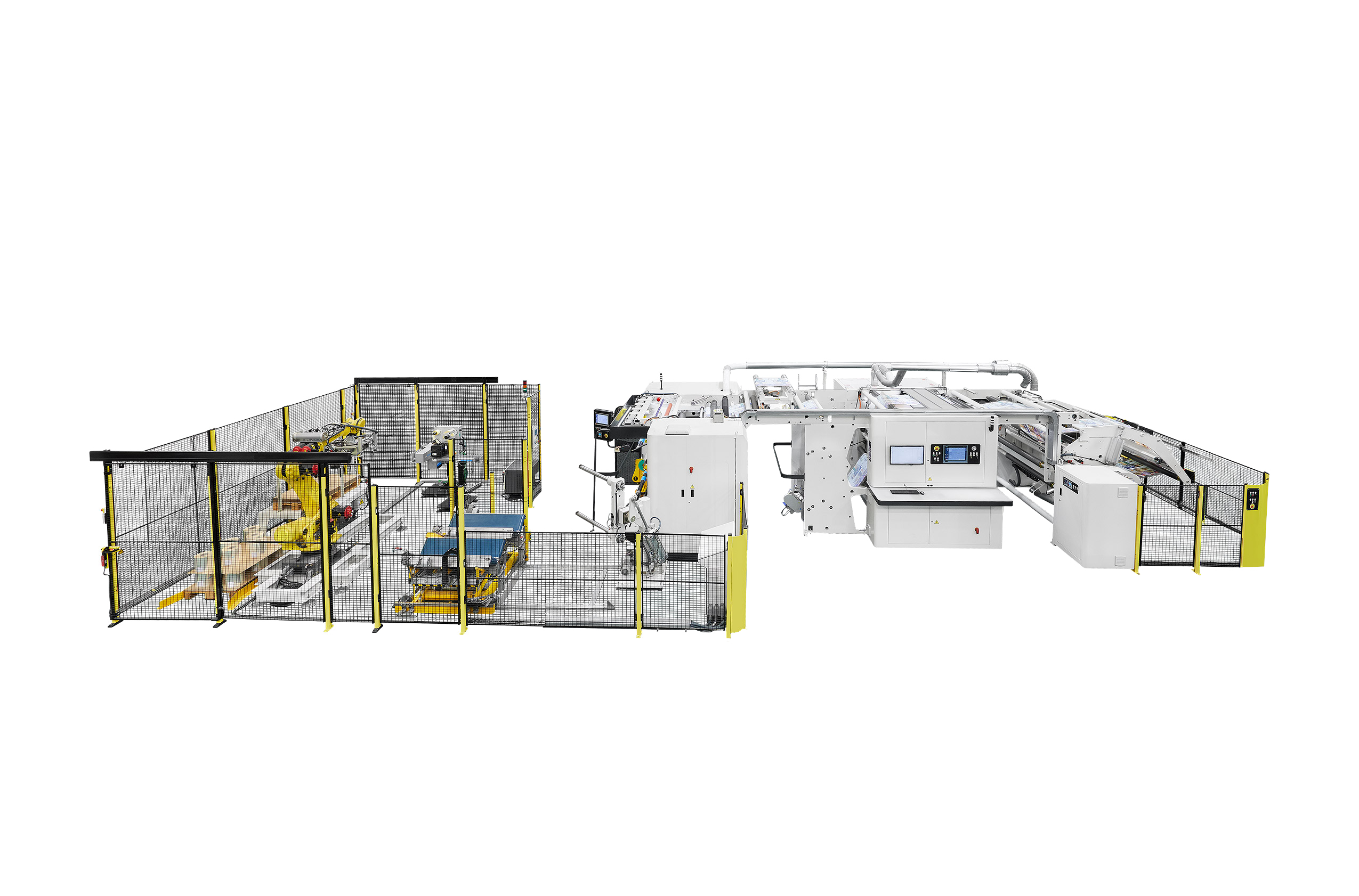

We offer global solutions in printing, laminating and slitting

We are a global partner for the flexible packaging. From printing to end of line automation processes, Comexi offers you a wide range of innovative solutions. Our 360º Service is by your side from the very beginning and throughout your machine’s life-cycle.

Keep up-to-date with the latest news and discover the most relevant events in our Latest News section!

Comexi Leads Innovative MADAM Project for Improved Packaging Production

Comexi Leads Innovative MADAM Project for Improved Packaging Production March 27, 2024...

Pioneering Innovation and Sustainability: Insights from Comexi’s President, Manel Xifra and Hotpack Global’s Founder, Abdul Jebbar

Pioneering Innovation and Sustainability: Insights from Comexi’s President, Manel Xifra and Hotpack...

Comexi Unveils Cutting-Edge Technological Center in Miami, Marking a Milestone in Flexible Packaging Industry

Comexi Unveils Cutting-Edge Technological Center in Miami, Marking a Milestone in Flexible...