WORK SMARTER, NOT HARDER

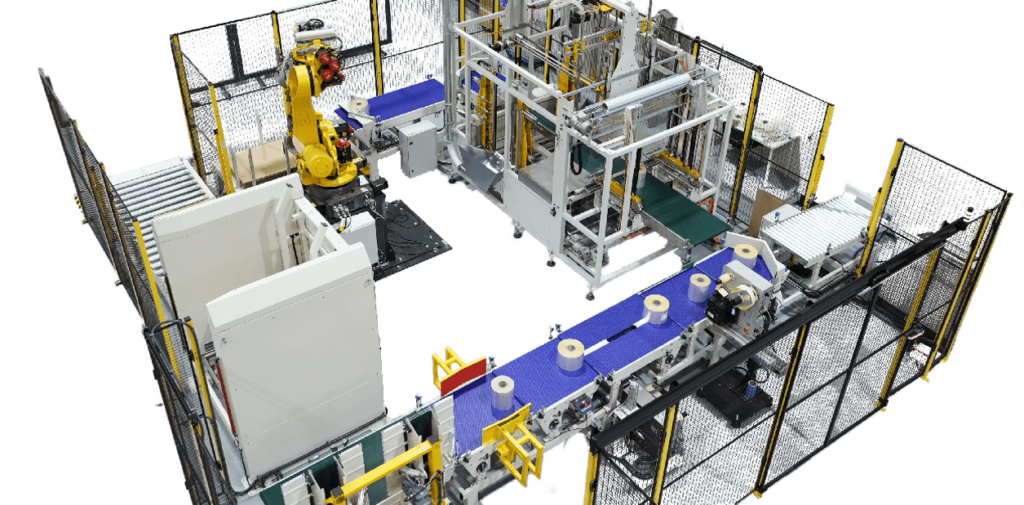

Comexi Reel Handling

Our benefits for printers are not an option, rather a necessity.

Less dependency on operator experience

In a short time a new operator is able to achieve optimum results, as the automated machine makes complex processes much simpler.

Higher productivity with high quality

Automating processes avoids human error and increases productivity. It also ensures customer loyalty through satisfaction in the results quality and zero error.

Improved labour management

Reduction of the workforce required, lower labour costs and a drastic reduction in sick leave. In addition, gender equity is achieved by avoiding heavy labour.

Sustainability: energy and material savings

Automated processes optimise energy consumption and reduce material waste in each process, resulting in more sustainable solutions and a lower carbon footprint in production.

Return on investment in less than 1 year

Automating processes may seem like an expense at first glance, but the high productivity it brings, plus the huge savings in energy and salary costs, make the return on investment very short.

Fully customizable modular design

Automating processes may seem like an expense at first glance, but the high productivity it brings, plus the huge savings in energy and salary costs, make the return on investment very short.

Traceability control

All you need to know.

PHASE I: Reel extraction from the slitter

PHASE II: From extraction to bagging

PHASE III: From bagging to palletizing

PHASE IV: Wrapping pallet and logistics

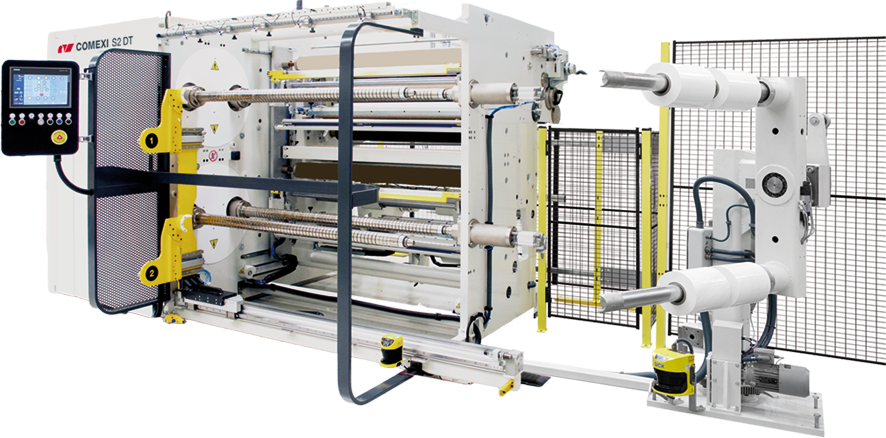

| Speed | 1312 / 1476.3 ft/min |

| Web width | 52.4 in |

| Max. reel diameter | 39.4 in |

| Max. reel weight | 2205 lb |

| UW web tension | 20 - 200 N (Opt 500 N) |

| RW web tension | 40 - 350 N ( Opt 550 N) |

| Speed | 400 / 450 m/min |

| Web width | 1330 mm |

| Max. reel diameter | 1000 mm |

| Max. reel weight | 1000 kg |

| UW web tension | 20 - 200 N (Opt 500 N) |

| RW web tension | 40 - 350 N ( Opt 550 N) |

Close-up.

The perfect team for the perfect process.

Slitting

DOUBLE PRODUCTIVITY THE SIMPLE WAY

The S2 DT is a compact slitter with double turret system that doubles the productivity of double shaft slitters. Together with its great ergonomics, it turns out to be the perfect combination of productivity, quality and versatility.

Laser

ADDED VALUE FOR YOUR PACKAGING WITH LASER APPLICATIONS