Efficiency and precision in unwinding and rewinding

Comexi Energy Winders

Guaranteeing reel quality with Comexi Energy Winders. Fitted with a non-stop turret system for a continuous process, it guarantees soft and controlled web deployment, therefore ensuring a perfect end result.

Our benefits are not an option, rather a necessity.

Maximum reel quality

Web tension control via highly sensitive electronic equipment for ensuring perfect rewinding and unwinding quality.

Ergonomics and easy use.

Fitted with two independent motors

Fast, tool-less locking system.

Control board with all the push buttons for activating the reel change.

Made in Europe

Machinery made in Europe.

70 years’ experience in reel to reel solutions.

All you need to know.

Ewinder 1000

| Speed | 23,600 in/min | |

| Reel diameter | up to 40 in | |

| Maximum width | up to 60 in | |

| Maximum reel weight | 1,250 kg | |

| Shaft and shaftless versions | ||

| Inside core diameter | 3" and 5" | |

| Double turret | ||

| Non-stop splicing technology |

| Speed | up to 600 m/min | |

| Reel diameter | up to 1,000 mm | |

| Maximum width | up to 1,520 mm | |

| Maximum reel weight | 1,250 kg | |

| Shaft and shaftless versions | ||

| Inside core diameter | 3" and 6" | |

| Double turret | ||

| Non-stop splicing technology |

Ewinder 1350

| Speed | 23,600 in/min | |

| Reel diameter | up to 53 in | |

| Maximum width | up to 60 in | |

| Maximum reel weight | 1250 kg | |

| Shaft and shaftless versions | ||

| Inside core diameter | 3" and 6" | |

| Double turret | ||

| Non-stop splicing technology |

| Speed | up to 600 m/min | |

| Reel diameter | up to 1,350 mm | |

| Maximum width | up to 1,520 mm | |

| Maximum reel weight | 1,250 kg | |

| Shaft and shaftless versions | ||

| Inside core diameter | 3" i 6" | |

| Double turret | ||

| Non-stop splicing technology |

The perfect team for the perfect process.

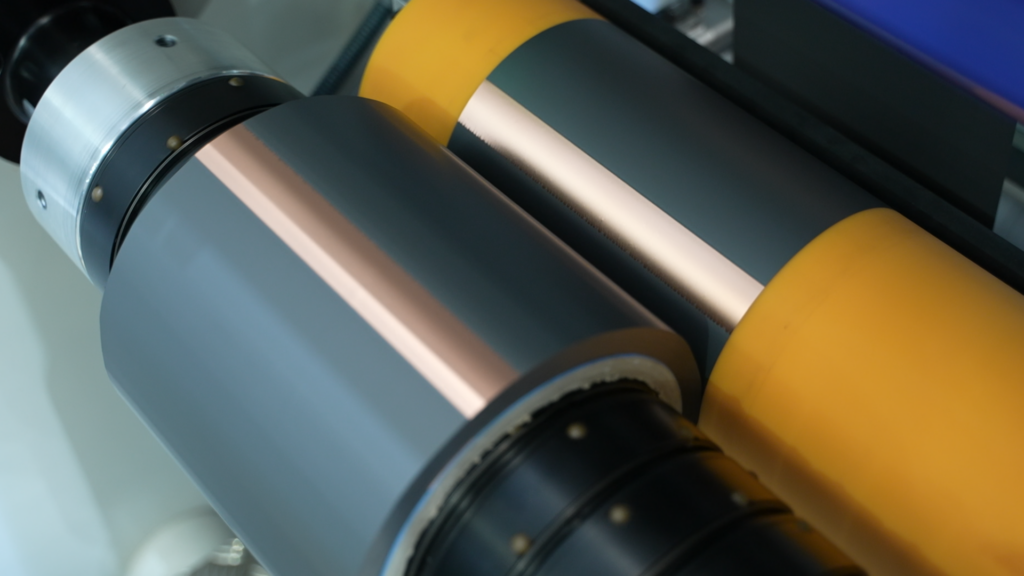

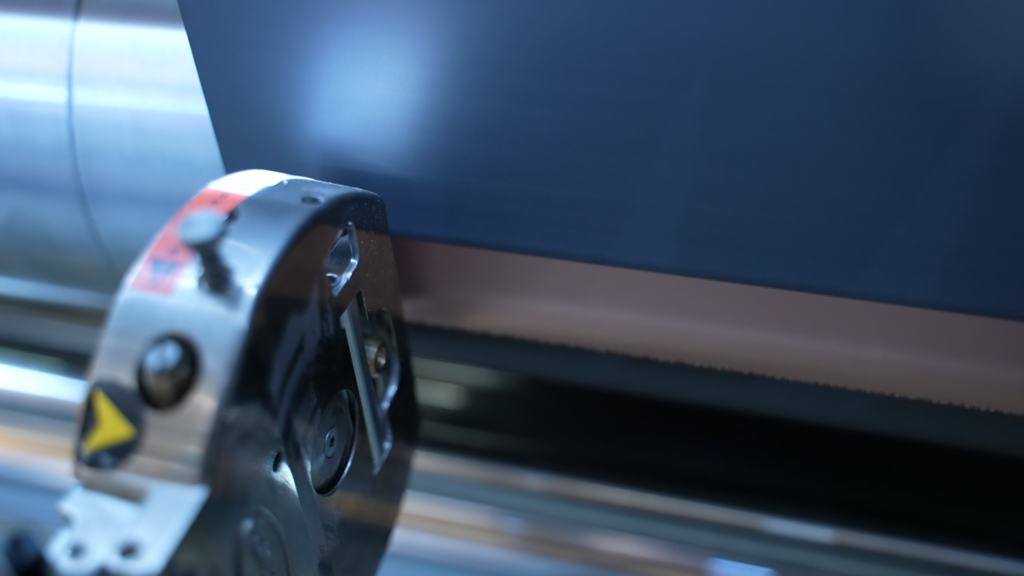

Slitters for electrodes made in Europe

S4 Energy

Slitters specially designed to deal with battery electrode materias such as coated copper and aluminium, and the different films and papers required for the battery separator.

Slitters for electrodes made in Europe

S2 Energy

Slitters specially designed to deal with battery electrode materias such as coated copper and aluminium, and the different films and papers required for the battery separator.