Designed to meet your needs

ML2 Evolution

Our benefits are not an option, rather a necessity.

Tailor-made solution

ML2 evolution can be configured in more than just a thousand ways. We manufacture the laminating machine you need, with all the adjustments, safety elements, special needs of your facilities. Ask us what you need and our team will get to work.

Autonomy

With innovations that facilitate use for any operator.

High performance register control. The system reads spacial marks in the printed film and compares them with the lacquer applied, then corrects it accordingly

Automatic trolley coupling: that reduces changeover time.

Closed loop system in SL: the machine automatically regulates the weight of the coating without intervention by an operator.

Peripheric’s integration: All external equipment is centralized to register full recipes and to avoid common errors.

Cloud: production analytics: Plant monitoring, Production control, Performance indicators & Technical service.

Automation & Connectivity

To reduce production and inefficiencies.

User-friendly HMI.

Operation tutorials.

Easy ergonomics.

Cloud ordering online (COOL): 24h assistance.

Web guide sensor

Versatility in applications

Capable of laminating virtually any material.

Many coatings solutions: solvent based, water based, solvent-less, cold seal, heat seal.

The finest film tension control even for recycled films.

Reel and web handling for any material.

Paper solutions.

Triplex and custom configurations.

All you need to know.

Functional Trolleys with Multiple Coating Solutions

Modular Drying Tunnel

Full control through user friendly HMI

Three-roller NIP

State-of-the-art low consumption engines

Mark-to-mark High Precision Register Control

Fully integrated Closed Loop Coating Weight System

| Type of adhesive | Solvent Based / Solventless / Water Based / UV | |

| Speed | 1476.4 ft/min | |

| Maximum web width | 36.6 / 52.4 / 60.2 in | |

| Maximum reel diameter | 39.4 in | |

| Core diameter winder | 3 / 6 in | |

| Maximum reel weight | 2205 lb | |

| Accessories / Optionals | High weight winders for paper, integrated laser for window packaging, Integrated coating sensor weight, automatic turret winders, high tension kit for thick films / paper, holography for eye-catching purposes, wet lamination. |

| Type of adhesive | Solvent Based / Solventless / Water Based / UV | |

| Speed | 450 m/min | |

| Maximum web width | 930 / 1330 / 1530 mm | |

| Maximum reel diameter | 1000 mm | |

| Core diameter winder | 76 / 152 mm | |

| Maximum reel weight | 1000 kg | |

| Accessories / Options | High weight winders for paper, integrated laser for window packaging, integrated coating sensor weight, automatic turret winders, high tension kit for thick films / paper, holography for eye-catching purposes, wet lamination. |

Close-up.

The perfect team for the perfect process.

Flexo

TOP PRINTING SPEED EASIER THAN EVER

Print with the highest quality and at 600 m/min at the touch of a button. If you are looking for 10 colors and better choice for extended color gamut, and optimize energy costs, the F2 Evolution is the flexo printer for you. A new generation of flexo printers that offer greater efficiency and print quality and greater ease of use.

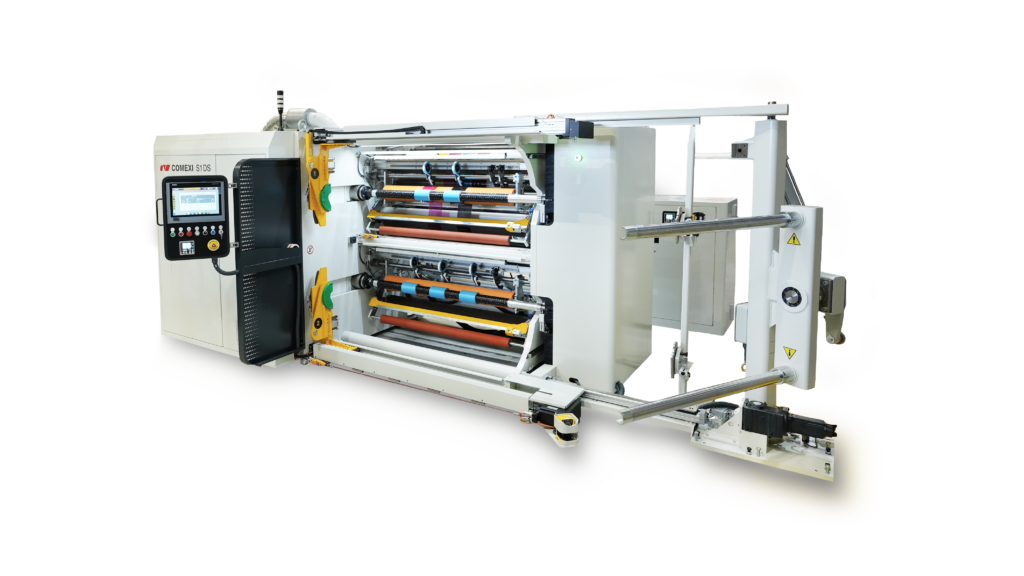

Slitting

THE REVOLUTION OF VERSATILITY

Recommended for working with large diameter reels. The slitter to meet the materials of any complexity and application. The automated processes and the acceleration ramps of the Comexi S1 DS achieve high productivity and introduce a user-friendly way of working.

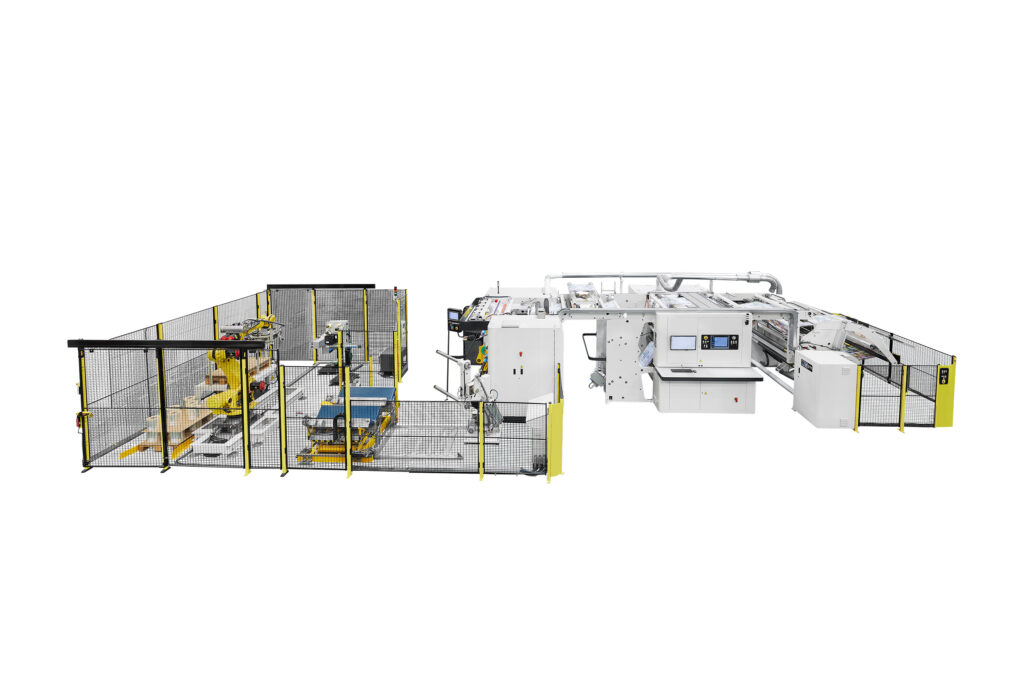

Reel handling

WORK SMARTER, NOT HARDER