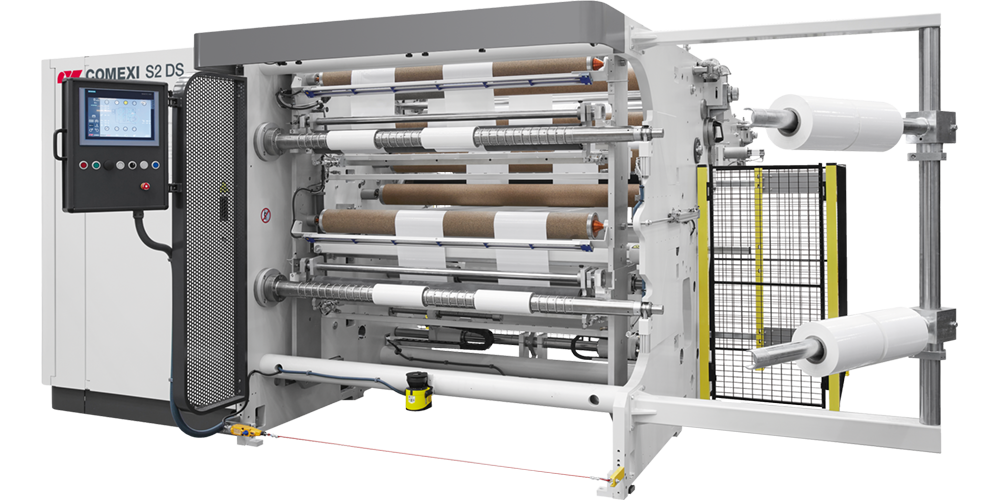

High-end slitters for perfect results

Comexi battery separator

In the battery industry, the quality of each process is crucial to keep costs at bay and not create material waste. Comexi slitters offer highly innovative solutions that focus on productivity and the high quality of the resulting reels.

Our benefits for battery manufactures

Automation and ease of use

Ergonomic and easy to use thanks to tools such as the touch panel PC, which allows you to adjust the work rate of the slitter and store production data.

Reduce changeover times with automatic core positioning.

Automatic touch to close the last reel and start a new one.

Ergonomic rewinder: Automatic push reel and rotation manipulation.

Usability: user-friendly and extremely intuitive HMI.Comexi Cloud to measure machine efficiency, production times, energy costs…

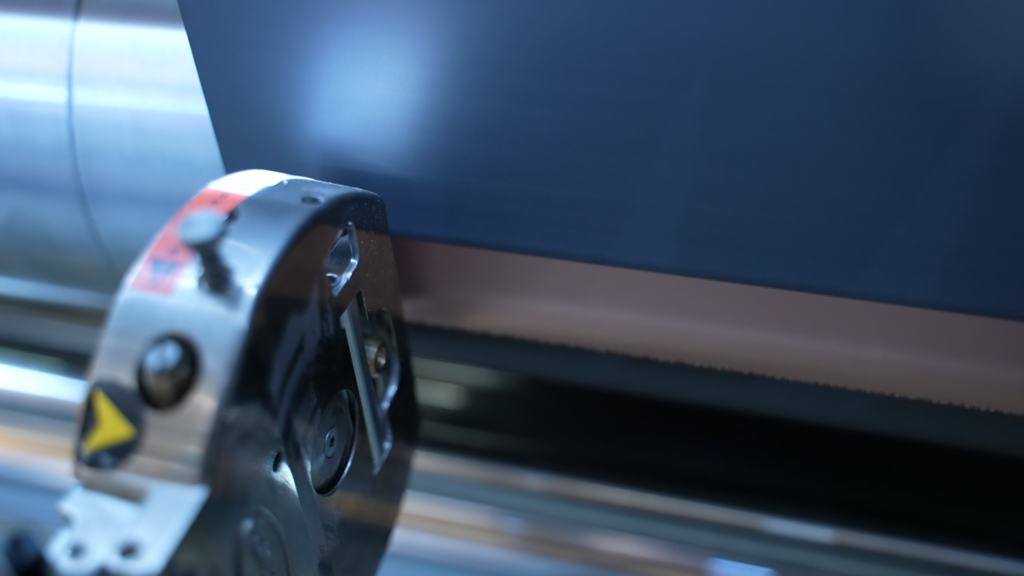

Energy efficiency

Consumes up to 80% less energy thanks to the energy reuse system of the regeneration system unwinder and rewinder motors.

Highly configurable

Solutions with or without turret.

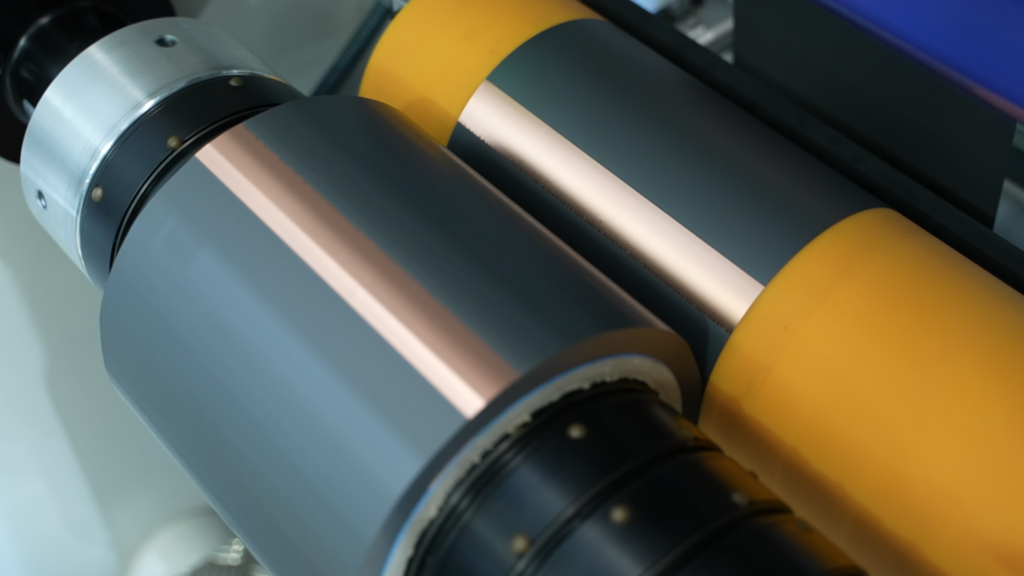

Suitable for a multitude of materials and structures

The perfect team for the perfect process

Electrode slitters made in Europe

| Web material speed | from 20 to 150 m/min |

| Max. incoming reel OD | 600 mm |

| Foil thickness | 6 – 15 µ |

| Rewinder type | Duplex |

| Max. output reel OD | 600 mm/800 mm |

Electrode slitters made in Europe

| Web material speed | from 20 to 150 m/min |

| Max. incoming reel OD | 1000 mm |

| Foil thickness | 6 – 15 µ |

| Rewinder type | Duplex |

| Max. output reel OD | 800 mm |

Efficiency and precision in unwinding and rewinding

| Speed | 23,600 in/min | |

| Reel diameter | up to 40 in | |

| Maximum width | up to 60 in | |

| Maximum reel weight | 1,250 kg | |

| Shaft and shaftless versions | ||

| Inside core diameter | 3" and 5" | |

| Double turret | ||

| Non-stop splicing technology |