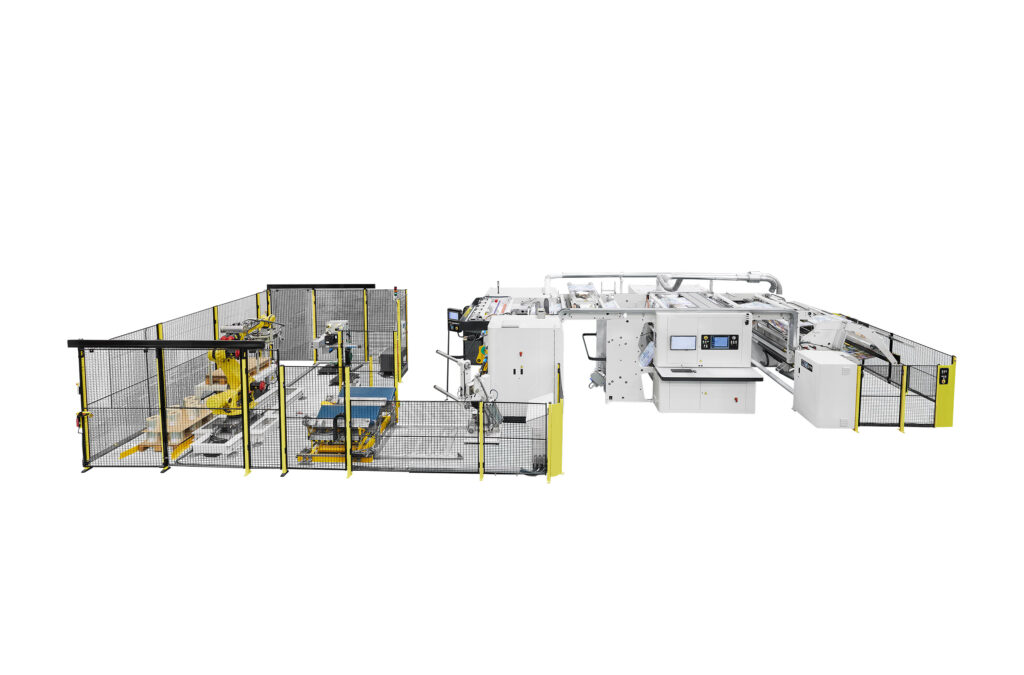

The perfect fit for automation and laser

Comexi S1 DT

If you are wondering how to meet your big production demands and improve productivity and profitability, the Comexi S1DT slitter is your answer. Fully automatic solution for all your complex materials and applications. Ideal for integrating laser solutions and automated end-of-line solutions.

Our benefits are not an option, rather a necessity.

Produce more in less time

A completely automatic solution from unwinding to rewinding, and an increase in productivity thanks to the double turret.

Maximize your efficiency achieving shorter cycle times with high slitting speeds and accelerations ramps up/down.

Ergonomic unwinder: pivoting Splice table with vacuum system for triplex materials.

Easy and fast to interchange slitting methods: Razor and circular knives being set in different shafts. Automatic knife positioning. Automatic knife laser pointer.

Automatic and easy to use

Ergonomic and easy to use thanks to tools such as touch Panel PCs, which enable you to set the work rate of the slitter and store production data.

Reduce changeover times with automatic core positioning.

Automatic tapping to close the final reel and start a new reel.

Ergonomic rewinder: Automatic push reels and hangling rotate.

Usability: User friendly and extremely intuitive HMI.

Comexi Cloud.

Materials of any complexity

Prepared to work with thick laminates or complex materials.

Over speed & over tension after slitting station: 2nd NIP: It allows to work with circular knives in “kiss cut” with 95-98% of materials, ensures no movement of the material and It helps for circular knives “kiss cut” and razor Gillette.

Work in tangential or kiss cut.

V8 version: overhead web path: ideal for food packaging and pharma packaging.

Razor and Circular knives being set in different shafts.

Reliable machinery (frame 50 mm)

Tension Isolation using a NIP

Closed loop system with Dancing roller (UW) and load cell (RW)

State of the art rewinding technology for different slitting configurations.

Your own configuration

It adapts to your needs, making it possible to customize the slitting with multiple optionals.

Easy and fast to interchange slitting methods.

Modular design: add on-line processes as AVT inspection, labeling.

Reel Handling: add a end-of-line automation system to push your productivity.

V6: Speed up to 600 mts/min, with underneath web path and Advanced Linear Track System.

V8: Speed up to 800 m/min, with overhead web path and Independent Advanced Linear Track System.

All you need to know.

Automatic push reels and handling rotate

User friendly and extremly intuitive HMI

Suport arm for turret rotation

Double shaft for double productivity

S1 DT V6

| Speed | 1968.5 ft/min | |

| Material width | 3 to 5.6 ft | |

| Parent roll diameter & weight | 3.3 ft | |

| Web path | Underneath | |

| Slitting width | 0.13 ft | |

| Rewinding system | Turret | |

| Finished roll diameter | 2 ft | |

| Acceleration ramps | 30 sec | |

| Turret rotation | 20 sec | |

| Type of rewinder system | ALTS lay-on | |

| Finished roll weight x shaft | 280 kg |

| Speed | 600 m/min | |

| Material width | 900 to 1700 mm | |

| Parent roll diameter & weight | 1000 mm (1T) | |

| Web path | Underneath | |

| Slitting width | 0 mm | |

| Rewinding system | Turret | |

| Finished roll diameter | 610 mm | |

| Acceleration ramps | 30 sec | |

| Turret rotation | 20 sec | |

| Type of rewinder system | ATLS lay-on | |

| Finished roll weight x shaft | 280 kg |

S1 DT V8

| Speed | 2624.7 ft | |

| Material width | 35.4 to 66.9 in | |

| Parent roll diameter & weight | 51.1 in (2T) / 59.0 in (3T) | |

| Web path | Overhead | |

| Slitting width | 0.78 in | |

| Rewinding system | Turret | |

| Finished roll diameter | 24.0 in | |

| Acceleration ramps | 20 sec | |

| Turret rotation | 20 sec | |

| Type of rewinder system | Bi Advanced Linear System Independent | |

| Finished roll weight x shaft | 320 kg |

| Speed | 800 m/min | |

| Material width | 900 to 1700 mm | |

| Parent roll diameter & Weighw | 1300 mm (2T) / 1500 mm (3T) | |

| Web path | Overhead | |

| Slitting width | 20 mm | |

| Rewinding system | Turret | |

| Finished roll diameter | 610 mm | |

| Acceleration ramps | 20 sec | |

| Turret rotation | 20 sec | |

| Type of rewinder system | Bi Advanced Linear System Independent | |

| Finished roll weight x shaft | 320 kg |

Close-up.

The perfect team for the perfect process.

Laminator

DESIGNED TO MEET YOUR NEEDS

Laser

ADDED VALUE FOR YOUR PACKAGING WITH LASER APPLICATIONS

Reel handling

WORK SMARTER, NOT HARDER