To achieve the perfect reel

Comexi DM1

With Comexi DM1, forget about inspecting every metre of material to check the quality of the rolls. With our media inspection and rewinding system, you can detect all printing, lamination and splicing defects before moving on to the next stages of production.

Our benefits are not an option, rather a necessity.

Avoid expensive mistakes

Specially for expensive multilayer applications: coffee, pharma, cosmetics

Allows to check and eliminate all issues in mother reels before doing expensive multilayer applications.

Increase efficiency and quality in downstream processes

Increases between 30-40%

100% video inspection

Ideal for extrusion lamination: very high cost of stop and start.

Make bigger reels

Add up several small reels to create a bigger one

All you need to know.

Video inspection to detect 100% of mistakes.

DM rewinds in both sides

Splicing table for perfect removal of errors

| Web material speed | 600 m/min | |

| Max. web width | 1700 mm | |

| Max. input reel OD | 1000 mm | |

| Max. output reel OD | 1000 mm | |

| Splice table | Yes | |

| Both directions rewinding | Yes | |

| Slitting in line | Optional | |

| Video | Optional | |

| Workflow link | Optional | |

| Max. rewinder weight | 1500 kg |

Close-up.

The perfect team for the perfect process.

Laminator

DESIGNED TO MEET YOUR NEEDS

Laser

ADDED VALUE FOR YOUR PACKAGING WITH LASER APPLICATIONS

Control, precision and speed are the words that best define this innovative tool that enables customising and differentiating, while also performing a wide range of applications and finishes.

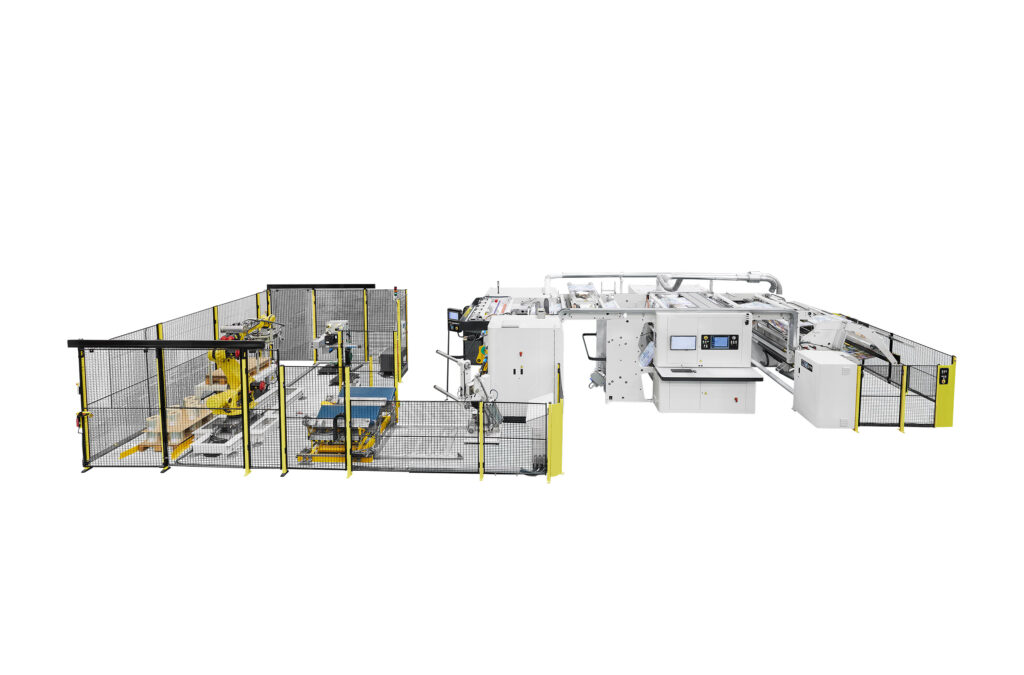

Reel handling

WORK SMARTER, NOT HARDER

How to meet your big production demands and improve productivity and profitability? Comexi S1DT slitter is the answer. Fully automatic solution for all your complex materials and applications.