A step ahead in sustainability and quality

Comexi Offset CI evolution

Comexi Offset CI evolution is the ultimate printing solution for the most demanding customers. It includes unbeatable technology for laminated flexible packaging, surface printing monofilms, paper and labels.It offers unparalleled print quality and production speed, while also providing effective solutions to recyclability challenges. Its impressive design and anthropomorphic robot not only catch the eye, they make job changeovers as easy as possible.

Our benefits for printers are not an option, rather a necessity.

Sustainability

EB curing: electron beam curing polymerizes the ink immediately without speed limitation.

No photoinitiators: this avoids the risk of migration and is perfectly adapted to the printing needs of food packaging.

Lower thermal impact: the EB system does not require heat for drying, which avoids film deformation and stretching problems.

Solvent Free: EB inks and coatings are the optimal solution to replace solvents, reducing emissions, consuming less ink and energy, as well as creating a safe environment for the printing process.

Lower energy consumption: as there is no need to evaporate solvents, the total energy consumption of an EB printer is lower than in other processes.

Recyclability: EB inks and coatings are highly resistant to chemicals, heat, sealing, and scratching, thus providing genuine replacement solutions, which are more recyclable and efficient than complex laminations. This is achieved by reducing the number of layers, and makes the Offset CI the pre-eminent solution for recyclable packaging.

Offset plates are made of aluminum, fully recyclable.

Fast time to market

Prepress and makeready times are very fast.

CTP: Computer to Plate lithographic plate engraving technology allows immediate job preparation, a set of plates is obtained in 20 minutes.

Production planning: short prepress and makeready times provide flexibility and enable rush orders to be processed.

Job data storage and recall: to have the press ready in minutes.

Very high print quality

High definition: offset allows very high screen linearture which gives excellent photographic and gradient reproduction. The high pigmentation of the inks allows high quality and high contrast prints.

High standardization of the pre-press process.

Very competitive printing costs

Thanks to lower plate costs, reduced stock storage, and less material waste.

Thinner films and reduction of waste.

Lithographic plates and prepress: extremely fast and economical plate image design.

Reduction of printed stocks: the speed and reduced cost of prepress allows to work with individual short runs at very competitive prices.

Reduced daily maintenance: thanks to EB inks, it is not necessary to clean the printing units daily.

Grouping of designs: offset technology facilitates the grouping of designs, which reduces the number of changes.

Expand your market to other products

Attract the leading brands in sustainability.

Highly demanding job markets: high print quality will allow you to offer jobs in sectors that demand high print definition.

Attract new customers thanks to fast prepress speed and retain existing customers thanks to fast service response.

Lead the way in sustainability and recyclability. The absence of solvents, energy reduction and reduction in carbon footprint will attract the leading brands in sustainability.

Offset printing for flexible packaging and labeling (Ctec course)

All you need to know.

Quality: Video inspection and color control

Sustainability: EB curing equipment

7 Offset + 1 Flexo around Central Impression cylinder

Fast changeover and ergonomics

Easy Access with internal platforms

Close-up.

The perfect team for the perfect process.

Laminator

DESIGNED TO MEET YOUR NEEDS

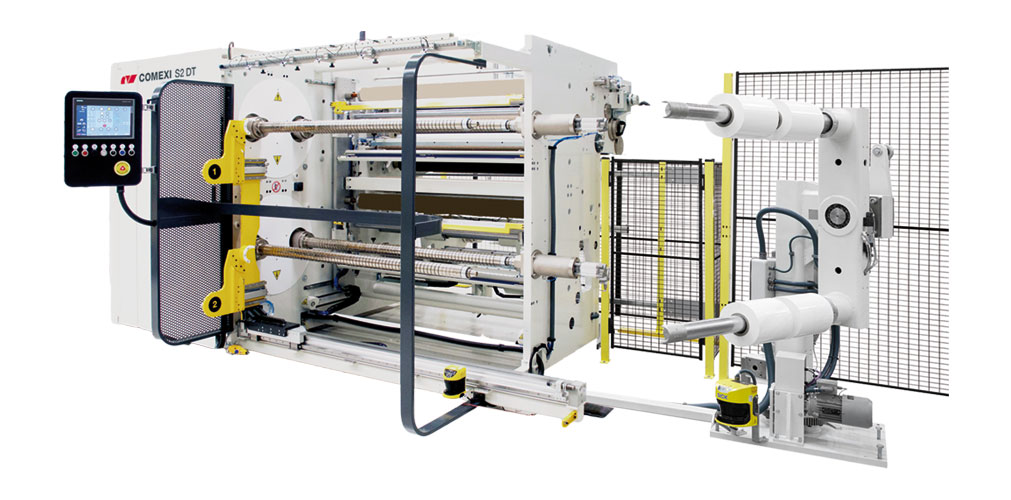

Slitting

THE PERFECT FIT FOR AUTOMATION AND LASER

If you are looking to meet high production demands, boost productivity, and enhance profitability, the Comexi S1DT slitter is the answer. Fully automatic solution for all your complex materials and applications. Ideal for integrating laser solutions and automated end-of-line solutions.